What are INFINAM® PA12 Black powders?

The innovative INFINAM® PA12 Black 3D-printable powders possess a relatively substantial amount of carbon black in the core of each particle. The carbon black particles are encapsulated in a polyamide shell during the precipitation-based production process. This allows for true pigmentation uniformity, minimizes visibility of surface abrasion and wear, as well as provides elevated resistance to ultraviolet rays and closer to isotropic mechanical performance compared to common PA based 3D printing powders. INFINAM® PA 6013 P is especially designed for an improved recyclability of the powder whereas INFINAM® PA 6014 P has a focus on the mechanical properties of the printed parts.

What are the advantages of INFINAM® PA12 Black powders?

The carbon black encapsulated powders offer high flowability and homogenous sintering. There is no carbon black dusting and no separation processes occur since the carbon black additive is embedded in the polymer particles. This also prevents the mechanical weakening of the particle adhesion at the sintered surfaces by free carbon black and allows for homogeneous heating of the powder from inside out, improving mechanical isotropy of the part. There is no dyeing step required to form black colored parts if the part surface is smoothened. Furthermore, the materials are characterized by increased UV resistance compared to PA12 parts without additives.

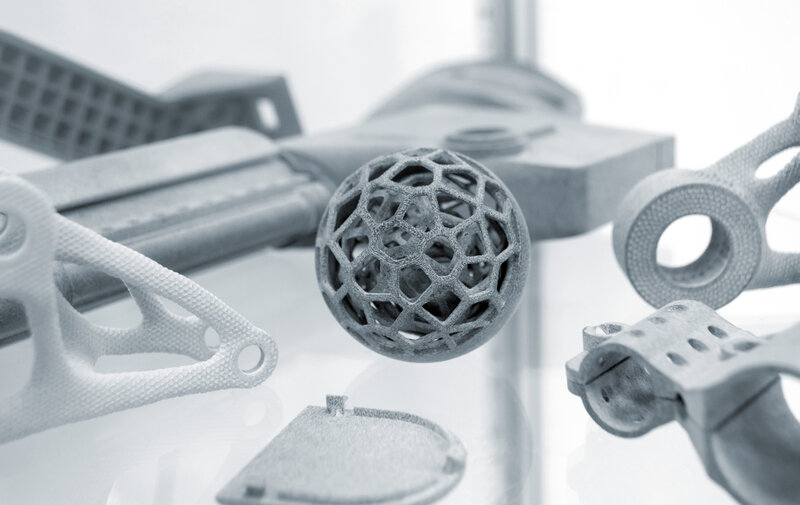

In which applications can INFINAM® PA12 Black powders be used?

INFINAM® is particularly suitable for manufacturing prototypes, manufacturing of individual units as well as serial parts. INFINAM® PA12 Black powders are ideal for producing 3D-printed items that require black color or resistance against visible surface contamination or scratches such as manufacturing aids and parts for the automotive, sports or aerospace industry.

Please contact us for an individual product recommendation!